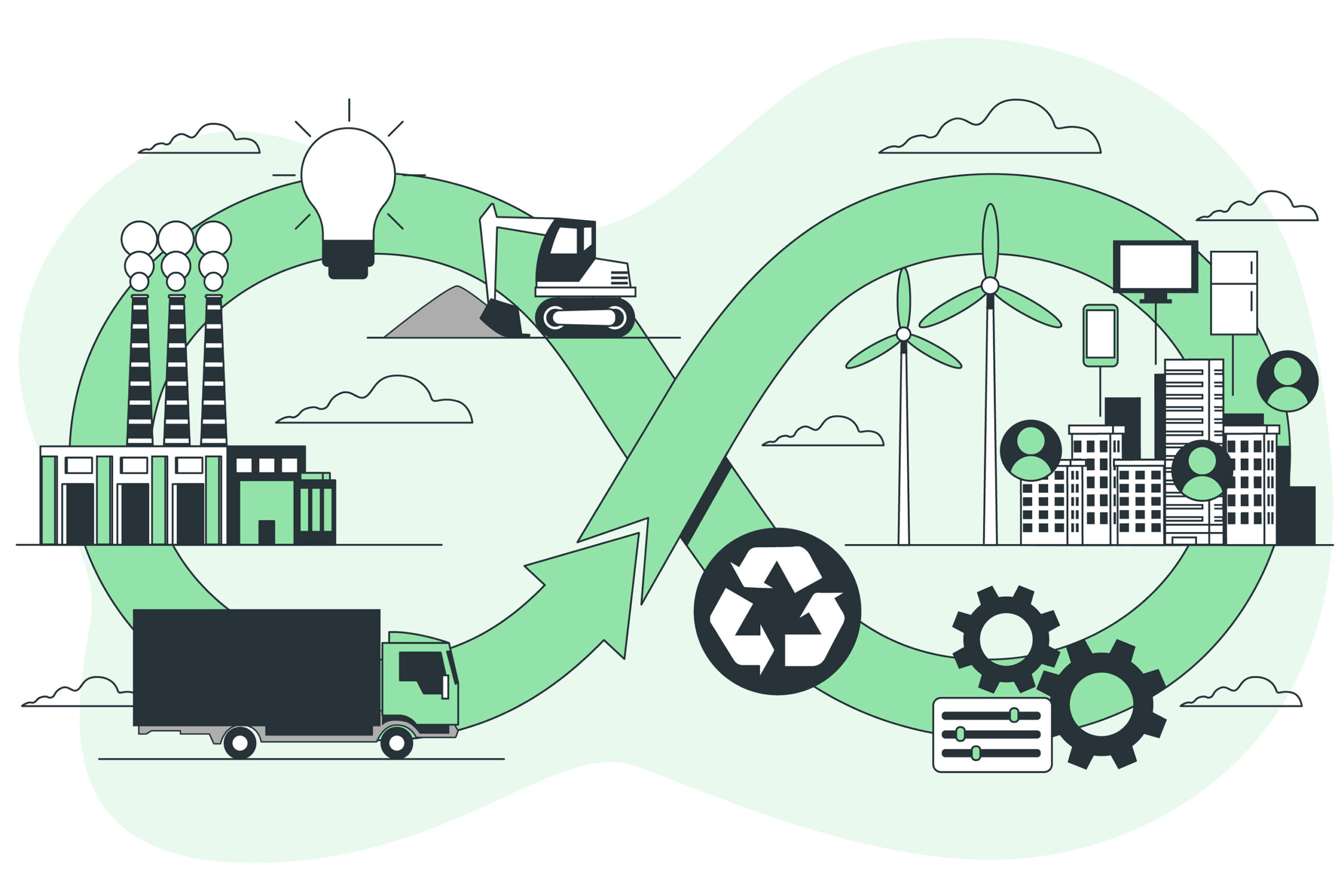

Sustainability Doesn’t Stop at Your Factory Gates

So your factory is now energy-efficient and green – that’s great. But what about all the parts and materials coming into your factory?

For many manufacturers, a large portion of their carbon footprint comes from the supply chain.

- The factories that make your raw materials or components might still rely on high-emission energy sources.

- To truly advance SDG 13 (Climate Action) and SDG 7 (Clean Energy), manufacturers must look beyond their own operations.

How to Green Your Supply Chain

The first step? Know your suppliers.

- More companies are now asking suppliers about their energy use and carbon footprint.

- Some manufacturers set sustainability requirements, such as:

- Using a percentage of renewable energy

- Meeting energy efficiency targets

Big Business Examples

- Walmart’s supply chain initiative: Aims to help suppliers cut one gigaton (one billion tons) of CO₂ collectively.

- The strategy? Small improvements across many suppliers lead to a massive overall impact.

How Your Company Can Contribute

1. Share Best Practices

- If your factory installed solar panels and saved money, share your experience with suppliers.

- Demonstrating cost savings can motivate suppliers to adopt green technology.

2. Collaborate on Energy Efficiency

- Conduct joint energy audits to identify inefficiencies.

- Host workshops on sustainable practices.

3. Provide Incentives for Green Investments

- Some manufacturers offer financing or incentives for suppliers to:

- Upgrade to energy-efficient machinery

- Transition to renewable energy sources

The Bigger Picture: Climate Action is a Team Effort

A single factory can be carbon neutral, but if its supply chain runs on fossil fuels, sustainability efforts fall short.

Why Greening the Supply Chain Matters

✅ Larger Climate Impact – Extending sustainability beyond your facility magnifies results.

✅ Risk Reduction – A cleaner supply chain is less vulnerable to future carbon regulations.

✅ Stronger Business Resilience – Sustainable suppliers ensure long-term stability and efficiency.

Conclusion: Every Link in the Chain Must Move Forward

Sustainability isn’t just about your factory—it’s about the entire supply network.

By working with suppliers, manufacturers can:

- Cut emissions on a larger scale

- Boost clean energy adoption

- Strengthen the sustainability of their entire industry

The transition to clean energy and climate-friendly manufacturing needs every link in the chain to move together.

Leave a Reply