Sustainable manufacturing is no longer a niche concept—it’s becoming the industry standard. With climate goals tightening, clean technologies advancing, and market expectations shifting, manufacturers must adapt. The future of energy-efficient, low-emission production will be shaped by key trends that align with SDG 7 (Affordable and Clean Energy) and SDG 13 (Climate Action).

1. 100% Renewable Energy & Energy Storage

Factories of the future will run entirely on renewable energy—whether through on-site solar and wind power or by purchasing clean electricity from the grid.

🔹 On-site generation: Many facilities are already installing solar panels, wind turbines, and battery storage to reduce reliance on fossil fuels.

🔹 Smarter energy sourcing: Even manufacturers without on-site generation are switching to renewable energy contracts as grids become greener.

🔹 Energy storage solutions: Large-scale batteries and AI-driven energy management systems will help stabilize energy use, ensuring clean power is available even at night or during low-wind periods.

✅ Future impact: As solar and wind power costs continue to drop, fully green-powered factories will likely become the industry norm, dramatically reducing emissions and energy costs.

2. Electrification & Green Fuels

Manufacturers are moving away from fossil fuel-powered equipment toward electric and hydrogen-based alternatives.

🔹 Electrification of industrial processes: High-energy processes like furnaces, boilers, and heavy machinery are shifting from coal and gas to electric versions, powered by renewables.

🔹 Green hydrogen & biofuels: Some industrial processes are difficult to electrify—here, green hydrogen and sustainable biofuels will serve as cleaner alternatives to fossil fuels.

🔹 Electric transportation: Many manufacturers are replacing diesel forklifts, trucks, and transport fleets with electric models to cut emissions across operations.

✅ Future impact: This transition will significantly reduce direct emissions, making factories less dependent on fossil fuels and helping them meet stricter climate targets.

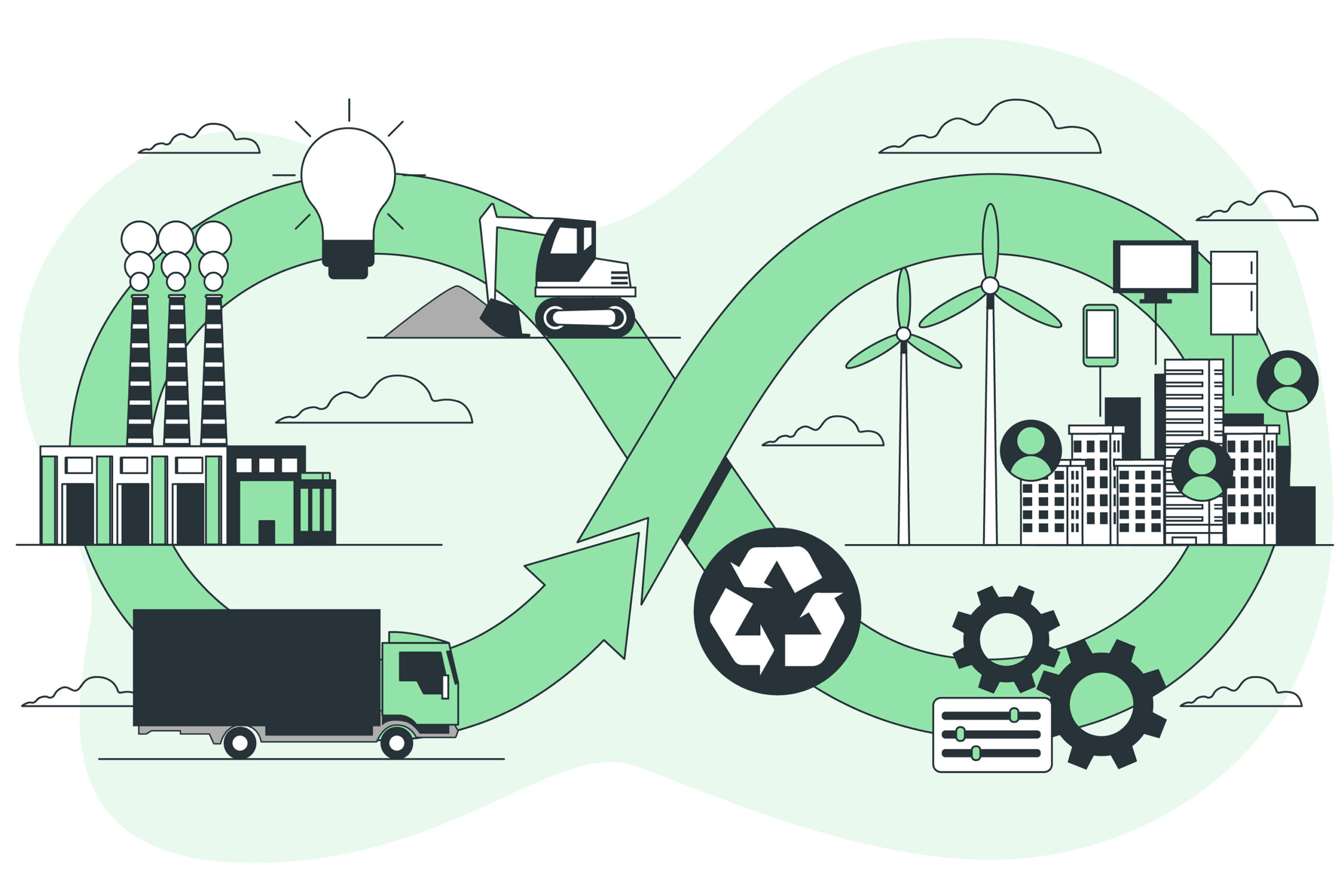

3. Circular Economy & Zero-Waste Manufacturing

Manufacturers are rethinking waste and material use, shifting toward a circular economy that minimizes environmental impact.

🔹 Designing out waste: Companies are developing closed-loop production systems where materials are recycled, reused, or repurposed instead of being discarded.

🔹 Reusing industrial byproducts: Some factories are selling or reusing waste materials, reducing the need for new raw materials and cutting emissions from production.

🔹 Sustainable product design: More manufacturers are creating easily recyclable products and using recycled materials in production.

✅ Future impact: Zero-waste manufacturing will reduce landfill waste, lower raw material demand, and drive significant energy savings by cutting the need for virgin materials.

4. Stricter Climate Goals & Regulations

Governments, investors, and customers are demanding greater transparency and accountability in sustainability efforts.

🔹 Net-zero commitments: Many manufacturers now have carbon neutrality targets for 2030, 2040, or 2050, requiring major investments in efficiency, electrification, and clean energy.

🔹 Carbon pricing & emissions limits: Expect more carbon taxes, stricter pollution laws, and incentives for low-carbon production.

🔹 Mandatory sustainability reporting: Investors and regulators are requiring detailed emissions data, making sustainability a business necessity rather than an optional initiative.

✅ Future impact: Companies that proactively invest in green technologies will gain a competitive edge, while those that delay may struggle to keep up with new regulations and market expectations.

The Road Ahead: A Smarter, Greener Industry

The future of manufacturing is cleaner, smarter, and more resource-efficient. With renewable energy, electrification, circular economy models, and stricter climate policies driving change, sustainable production will soon become the global standard.

✔ Factories powered by clean energy

✔ Low-carbon, energy-efficient processes

✔ Products designed for reuse and recyclability

✔ Stronger climate regulations pushing industries to innovate

Manufacturers that embrace these trends early will reduce costs, improve resilience, and lead the transition to a more sustainable future—benefiting both business and the planet.

Leave a Reply